Polymers Win World War II

Polymers Win World War II - The search for a lightweight, nonbreakable, moldable material began with the invention of vulcanized rubber. This material is derived from natural rubber, which is a semisolid, elastic, natural polymer. In the 1700s, natural rubber was noted for its ability to rub off pencil marks, which is the origin of the term rubber. Natural rubber has few other uses, however, because it turns gooey at warm temperatures and brittle at cold temperatures. Then, in 1839, an American inventor, Charles Goodyear, discovered rubber vulcanization, a process in which natural rubber and sulfur are heated together. The product, vulcanized rubber, is harder than natural rubber and retains its elastic properties over a wide range of temperatures. With the invention of vulcanized rubber came modern products such as waterproof boots, rain jackets, and, most importantly, the rubber tire. In the 1930s, more than 90 percent of the natural rubber used for manufacturing in the United States came from Malaysia. In the days after Pearl Harbor was attacked in December 1941 and the United States entered World War II, however, Japan captured Malaysia. As a result, the United States—the land with plenty of everything, except rubberfaced its first natural resource crisis.

The military implications were devastating because without rubber tires, military airplanes and jeeps were useless. Petroleum-based synthetic rubber had been developed in 1930 by DuPont chemist Wallace Carothers but was not widely used because it was much more expensive than natural rubber. With Malaysian rubber impossible to get and a war on, however, cost was no longer an issue. Synthetic rubber factories were constructed across the nation, and within a few years, the annual production of synthetic rubber rose from 2000 tons to about 800,000 tons.

The military implications were devastating because without rubber tires, military airplanes and jeeps were useless. Petroleum-based synthetic rubber had been developed in 1930 by DuPont chemist Wallace Carothers but was not widely used because it was much more expensive than natural rubber. With Malaysian rubber impossible to get and a war on, however, cost was no longer an issue. Synthetic rubber factories were constructed across the nation, and within a few years, the annual production of synthetic rubber rose from 2000 tons to about 800,000 tons.

Also in the 1930s, British scientists developed radar as a way to track thunderstorms. With war approaching, these scientists turned their attention to the idea that radar could be used to detect enemy aircraft. Their radar equipment was massive, however. A series of ground-based radar stations could be built, but placing massive radar equipment on aircraft was not feasible. The great mass of the equipment was due to the large coils of wire needed to generate the intense radio waves. The scientists knew that if they could coat the wires with a thin, flexible electrical insulator, they would be able to design a radar device that was much less massive. Fortunately, the recently developed polymer polyethylene turned out to be an ideal electrical insulator. This permitted British radar scientists to construct equipment light enough to be carried by airplanes. These planes were slow, but flying at night or in poor weather, they could detect, intercept, and destroy enemy aircraft. Midway through the war, the Germans developed radar themselves, but without polyethylene, their radar equipment was inferior, and the tactical advantage stayed with the Allied forces. Nylon was invented in 1937, which was just prior to World War II.

http://www.omkris.com/2012/05/polymers-win-world-war-ii.html

http://www.omkris.com/2012/05/polymers-win-world-war-ii.html

Aside from its use in hosiery, nylon also found great use in the manufacture of parachutes, important to the U.S. military. Up to that time, parachutes were made mainly of silk. The world’s foremost supplier of silk, however, was Japan. By the time World War II began, Japan had stopped exporting silk to the United States. The United States, however, now had nylon, which in many regards was better than silk. Over the course of the war practically all the nylon that DuPont could produce went to the military for the manufacture of a wide variety of nylon-based commodities suited for military purposes, such as parachutes, ropes, and clothing. Four other polymers that had a significant impact on the outcome of World War II were Plexiglas, polyvinyl chloride, Saran, and Teflon. Plexiglas, or poly(methyl methacrylate), is a glasslike but moldable and lightweight material that made excellent domes for the gunner’s nests on fighter planes and bombers. Both Allied and German chemists used poly(methyl methacrylate), but only the Allied chemists learned how small amounts of this polymer in solution could prevent oil or hydraulic fluid from becoming too thick at low temperatures. Equipped with only a few gallons of a poly(methyl methacrylate) solution, Soviet forces were able to keep their tanks operational in the Battle of Stalingrad during the winter of 1943.

While Nazi equipment halted in the bitter cold, Soviet tanks and artillery functioned perfectly, resulting in victory and an important turning point in the war.

|

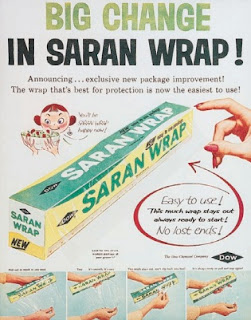

| The now familiar plastic food wrap carton with a cutting edge was introduced in 1953 by Dow Chemical for its brand of Saran wrap. |

Polyvinyl chloride (PVC) had been developed by a number of chemical companies in the 1920s. The problem with this material, however, was that it lost resiliency when heated. In 1929, Waldo Semon, a chemist at BFGoodrich, found that PVC could be made into a workable material by the addition of a plasticizer. In World War II, this material became recognized as an ideal waterproof material for tents and rain gear.

Originally designed as a covering to protect theater seats from chewing gum, Saran found great use in World War II as a protective wrapping for artillery equipment during sea voyages. (Before Saran, the standard operating procedure had been to disassemble and grease the artillery to avoid corrosion.) After the war, the polymer was reformulated to eliminate the original formula’s unpleasant odor and soon pushed cellophane aside to become the most popular food wrap of all time.

In the 1930s, Teflon was discovered serendipitously by chemists working at DuPont. Initially, the discoverers of Teflon were impressed by the long list of things this new material would not do. It would not burn, and it would not completely melt. Instead, at 620°F it congealed into a gel that could be conveniently molded. It would not conduct electricity, and it was impervious to attack by mold or fungus. No solvent, acid, or base could dissolve or corrode it. And most remarkably, nothing would stick to it, not even chewing gum.

http://www.omkris.com/2012/05/polymers-win-world-war-ii.html

http://www.omkris.com/2012/05/polymers-win-world-war-ii.html

Because of all the things Teflon would not do, DuPont was not quite sure what to do with it. Then, in 1944 the company was approached by governmental researchers in desperate need of a highly inert material to line the valves and ducts of an apparatus being built to isolate uranium 235 in the manufacture of the first nuclear bomb.

http://www.omkris.com/2012/05/polymers-win-world-war-ii.html

http://www.omkris.com/2012/05/polymers-win-world-war-ii.html

Thus Teflon found its first application, and 1 year later, World War II came to a close with the nuclear bombing of Japan. With a record of wartime successes, plastics were readily embraced in the postwar years. In the 1950s, Dacron polyester was introduced as a substitute for wool. Also, the 1950s were the decade during which the entrepreneur Earl Tupper created a line of polyethylene food containers known as Tupperware. By the 1960s, a decade of environmental awakening, many people began to recognize the negative attributes of plastics. Being cheap, disposable, and nonbiodegradable, plastic readily accumulated as litter and as landfill. With petroleum so readily available and inexpensive, however, and with a growing population of plastic-dependent baby boomers, little stood in the way of an ever-expandingarray of plastic consumer products. By 1977, plastics surpassed steel as the numberone material produced in the United States. Environmental concerns also continued to grow, and in the 1980s plastics recycling programs began to appear. Although the efficiency of plastics recycling still holds room for improvement, we now live in a time when sports jackets made of recycled plastic bottles are a valued commodity.

Key word : Win World War II, world war 2, poly (methyl methacrylate), saran wrap, plastics recycling programs